Flame Polishing

Flame polishing is a method used in manufacturing to polish the edges of thermoplastic with an open flame. Here at VKF, we are concentrated on the polishing of the thermoplastic acrylic. This method of polishing uses high temperatures to produce an edge on the acrylic that is glossy and smooth. This technique is used in order to enhance the overall appearance of the finished product.

This process is exactly as the name entails: using a flame to polish the edge of acrylic until it melts slightly. The heat of the fire causes the surface tension of the thermoplastic to melt, smooth out, and form a glossy surface. This process is then repeated until the desired finish is achieved.

Equipment Needed

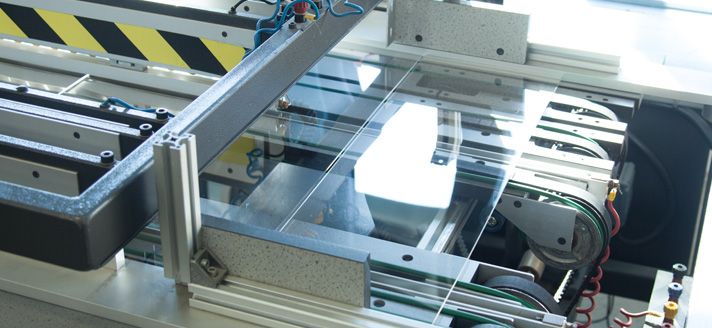

For this form of plastic polishing, the main tool needed is an oxy-hydrogen flame gun. For industrial uses, the machine used is easily adjusted to take different factors into account. Such factors include but are not limited to what kind of thermoplastic is being polished and what the size or thickness of that plastic is.

The oxy-hydrogen flame gun uses distilled water and electricity to create the oxygen and hydrogen for its flame. The machine is then adjusted so that the right size and shape flame is used for the product.

Process of Flame Polishing

- After sawing or shaping the product, clean the acrylic edges so that no more dust or debris remains

- File or sand to smooth any remaining uneven edges

- Use a low to medium flame to start heating the edges. The torch is then moved back and forth, keeping approximately 25 - 50 mm distance between the fire from the torch and the acrylic

- As the acrylic starts to melt, move the torch closer and continue to heat and move the flame along the ege until it becomes smooth and glossy

- Once the desired edge has been achieved, turn the torch off and allow the acrylic to cool

Advantages of Flame Polishing

- Aesthetically pleasing

- Durability

- Cleanliness

- Cost-effective

Flame polishing acrylic products creates a beautiful, smooth, glossy finish. The edges also become transparent, allowing light to pass through, enhancing the look of the material.

The melting, smoothing and recooling of the acrylic edges also strengthen the surface of the material. This makes the finished product more resistant to wear and tear such as scratches and abrasions.

This method of smoothing and polishing edges is relatively inexpensive compared to other methods. It also eliminates surface imperfections, making the final product easier to clean and sanitise.