Galvanization

This process is used to refine metal surfaces and make them more resistant to environmental influences. There are a few processes of galvanization, and each process applies a protective zinc layer to steel or iron in order to prevent rusting. In one method called electroplating, a metal is dissolved in a chemical solution with the help of electronic currents and transferred in a thin layer to the metal to be refined.A benefit of electro galvanization is that it produces a thinner form of galvanization. This method works best when a decorative coating of paint is to be applied. This gives a metal object a more beautiful appearance, e.g. special shine.

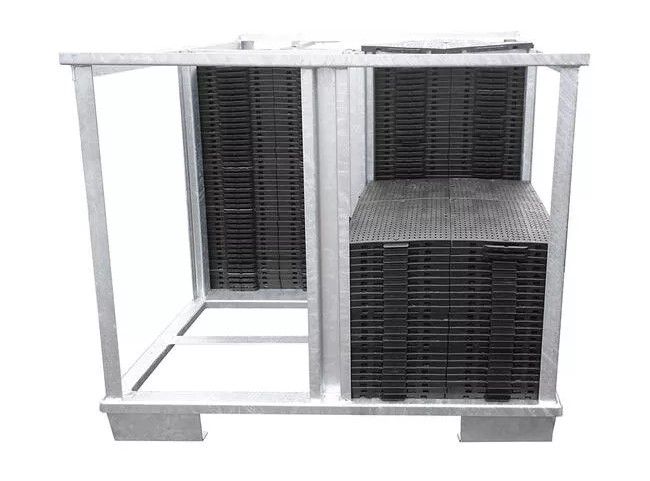

The most common method of galvanizing is the method of hot-dip galvanizing. This is where the metal parts are submerged in a bath of hot molten zinc. This method deposits a thick layer of zinc iron alloys onto the surface of a steel, aluminium or other metal item.

Advantages of Galvanization

- Durable and sustainable

- Reliable and cost effetive

- Predictable

- Tough and Protective

- Corrosion resistant

Galvanization is a method that has a fast turnaround rate and is time efficient. These two factors cut down on labour costs allowing the product to be more cost effective.

Galvanized Steel is a very thin, durable material that once applied to a steel structure, can last decades to come. This protective zinc coating against the elements and corrosion cuts down on repeated maintenance and therefore, the economic and environmental costs associated with these products.

Galvanized steel is also reliable, predictable, and replicable process, where unlike paint, the bond formed through this process is now part of the steel itself.

Because galvanization is so predictable, lifespans can easily be forecasted and relied upon with their quantifiable coating thickness. Its toughness also offers an abrasion resistance much better than paint coating.