Bringing Your Ideas to Life

through CAD 2D drawings and 3D models!

Computer Aided Design (CAD)

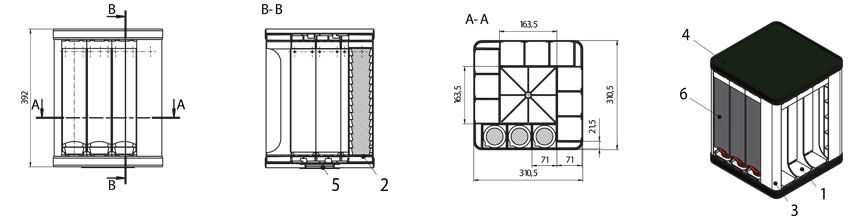

Computer Aided Design (CAD) refers to a kind of "electronic drawing board". CAD programs are not only used by engineers to create 2D technical drawings and mockups of conceptual designs, but are also used to create virtual 3D moving visualisation models of physical objects.

2D CAD models are flat and provide dimentional and layout information needed to build the structure. Examples of 2D CAD models include blueprints, floorplans, electrical diagrams, etc. 3D CAD is similar to 2D CAD, but with the ability to show the object in a three-dimensional way. This allows the team of engineers to see how all of the pieces fit together and operate in order to build the structure. With the help of this technology, we visualise our customers' ideas for individual displays made of various materials.

CAD software is used in all specialist areas in which constructions are developed. This includes examples such as plant engineering, mechanical engineering, shipbuilding, in dentistry, architecture, construction, as well as in fashion and product design.

CAD Drawing

When using CAD, a design is stored in a geometry database as a CAD data model. A CAD drawing is created on the basis of this model by outputting it to an output device, e.g. plotter, printer, or screen. A CAD drawing is understood to be, on the one hand, the output on the medium of paper, transparency, or similar - and on the other hand a specially prepared file or component of a file (which can be displayed on the screen).

Our Team at VKF Renzel

Here at VKF Renzel in Isselburg, we have our very own CAD Team. During the development of new products, our team uses CAD technology to bring their designs to virtual 3D visualisation.

As a customer, you can already see the final appearance of the product on the model at this stage. The advantage of CAD technology is that all further development processes are based on this digital data. This applies to sampling, prototyping, toolmaking as well as many of our plastic manufacturing processes such as extrusion, injection moulding, lasering, thermoplastic forming, milling or die-cutting.

Our CAD software is able to increase productivity and improve quality of design, which results in faster production and manufacturing of high quality products for our customers.

Advantages of CAD

- Accuracy

- Simulation testing and revisions

- Increased productivity

- Collaboration made easy

- Easy to understand

These drawings and models inlcude the important measurements of the design process and is able to be seen and easily shared among the team. This is helpful because everyone can view and review every stage of the process collaboratively. This allows teams who use CAD to work faster, smarter, and more effeciently, in turn making a more affordable desgin process.

Prototyping

Prototyping describes all processes in which a prototype is produced. Rapid prototyping refers to the rapid production of sample components based on design data. In this way, exisiting CAD data is directly and quickly converted into workpieces. We have here at VKF Renzel our own prototyping facility in our branch in Isselburg, Germany.Here at VKF Renzel, we can also 3D print small runs and prototypes. If you want to produce a new product, suitable component, or sparepart, we can first develop a prototype for you. If you want to present a specific 3D model at a tradeshow, or produce a small production run of complex components cost-effectively and promptly, then our 3D printing service is the right process for these tasks and many other concrens. Learn more about Prototyping >>