Polystyrene (PS)

Polystyrene is a thermoplastic polymer derived from styrene, which a colourless liquid hydrocarbon derived from petroleum.

This thermoplastic has many applications due to how versatile it is, including packaging, insulation, disposable containers and cutlery, and consumer goods.

PS is a transparent, amorphous and deep-crystalline thermoplastic and can be used as either a thermoplastic material or as a foam.

The Window Frame System contains polystyrene panels to prevent light from shining through the frame when using 2 posters. This material is ideal for this applications due to it being heat resistant, as well as not deforming or melting in the heat.

Let us take a look down below to see how the two PS forms, foam and thermoplastic, differ:

This thermoplastic has many applications due to how versatile it is, including packaging, insulation, disposable containers and cutlery, and consumer goods.

PS is a transparent, amorphous and deep-crystalline thermoplastic and can be used as either a thermoplastic material or as a foam.

The Window Frame System contains polystyrene panels to prevent light from shining through the frame when using 2 posters. This material is ideal for this applications due to it being heat resistant, as well as not deforming or melting in the heat.

Let us take a look down below to see how the two PS forms, foam and thermoplastic, differ:

Foam Form

Thermoplastic Form

PS in its foam form is also often called Styrofoam. It is a lightweight material that is formed into various shapes and sizes through methods such as extrusion and injection moulding.

Properties of Foam PS:

Properties of Foam PS:

- Lightwieght and versatile

- Good insulation

- Buoyant

- Chemical resistant

- Mouldable

Thermoplastic Polystyrene is sometimes referred to as TPS. TPS is also a material that can be shaped and moulded through processes such as extrusion and injection moulding.

Properties of Thermoplastic PS:

Properties of Thermoplastic PS:

- Hard and brittle

- High melting point

- Electrical insulator

- Chemical resistant

Foam Form

PS in its foam form is also often called Styrofoam. It is a lightweight material that is formed into various shapes and sizes through methods such as extrusion and injection moulding.

Properties of Foam PS:

Properties of Foam PS:

- Lightwieght and versatile

- Good insulation

- Buoyant

- Chemical resistant

- Mouldable

Thermoplastic Form

Thermoplastic Polystyrene is sometimes referred to as TPS. TPS is also a material that can be shaped and moulded through processes such as extrusion and injection moulding.

Properties of Thermoplastic PS:

Properties of Thermoplastic PS:

- Hard and brittle

- High melting point

- Electrical insulator

- Chemical resistant

Advantages of Polystyrene

- Lightweight

- Durability

- Low cost

- Insulation properties

Whether Polystyrene is in its foam or thermoplastic form, all of these characteristics apply as advantages for this versatile material.

It can be formed into many different shapes and sizes through extrusion and injection moulding.

PS is a material that is transparent, which is ideal for items such as table top leaflet holders. You can insert your advertising materials inside of these polystyrene brochure holders, and they will be seen through the transparent PS material.

Polystyrene is a very cost-effective product to produce, making it a low cost material for both the producer and consumer.

High-Impact Polystyrene (HIPS)

HIPS is a modified form of polystyrene with better impact resistance. This tougher and less brittle version of standard polystyrene is created by mixing polystyrene with an elastomer. This allows products made of HIPS to be able to absorb more energy if dropped without breaking.

HIPS is known for its thermal and good mechanical properties, as well as being cost effective to process.

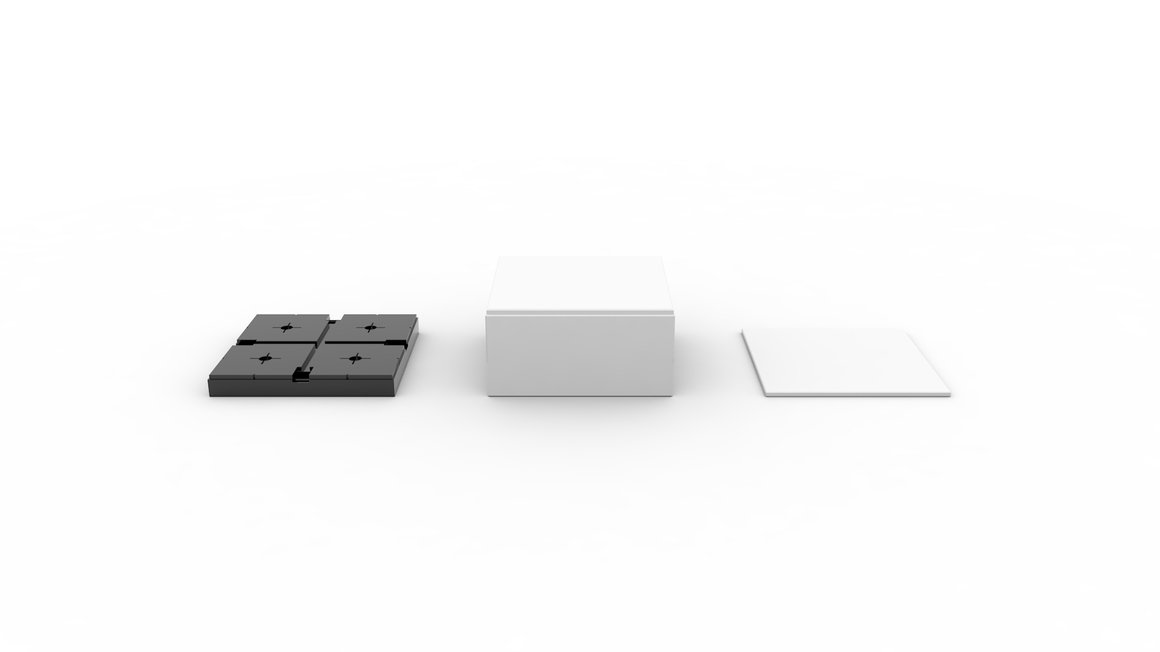

This material, unlike standard polystyrene, is not transparent. HIPS is an opaque material, which can easily be coloured and finished in different designs. This possibility makes HIPS a suitable option for a wide range of aesthetic applications, especially for products such as our EasyCubes System.

Advantages of HIPS

- Impact resistance and thermal stability

- Processability

- Cost-effective

- Aesthetic Variety

High-Impact Polystyrene is a much better choice for impact resistance than standard polystyrene due to its product formula.

It also has a higher thermal stability than standard polystyrene, allowing it to be in even higher temperatures without melting or degrading.

HIPS is relatively easy to manfacture and is able to be moulded by injection, extrusion, and can also be thermoformed.