Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) is an amorphous thermoplastic. The material is hard and brittle. Only by adding plasticizers and stabilisers does PVC become softer, more malleable, and suitable for technical applications. It is mainly used in floor covering and in the form of window profiles and pipes.PVC is divided into high-impact PVC (water distribution pipes, windows, flooring, and roofing), hard PVC (profiles and tablet packaging) and soft PVC (organiser bags, and banners for stretch frames). Let us get more into the differences between high-impact, hard and soft PVC.

Soft PVC

Soft PVC is a variation of PVC, which has been formulated with plasticisers to increase its elasticity and flexibility. Soft PVC is sometimes also known as flexible PVC.Once the plasticisers are added, they break up the tight structures of the PVC polymer chains. This allows the material to move more freely and therfore, the material is more flexible. The addition of platicisers also improves the material's resistance to impact and tearing. This make the PVC flexible, while remaining durable and strong.

Soft PVC is able to be high-frequency welded, which is a process that uses energy to create heat in order to melt the two PVC surfaces together. You can see the results of this kind of high-frequency processing with our different price holders. This technique is able to create multiple pockets out of one sheet of PVC to put prices and other additional information in.

Advantages of Soft PVC

- Flexible

- Resistant to chemicals

- UV light resistant

- Ability to be moulded

- Customisable

- Durable

Soft PVC is chemical resistant, which makes it suitable for in applications that require contact with solvents or other chemicals.

Soft PVC is also resistant to UV light, making it an optimal choice for outdoor uses, such as our crystal clear banner for the Aluminium Stretch Frame. This use can be seen in the picture to the left.

A very useful trait of Soft PVC is its versatility. This is because it can be moulded into complex shapes and designs, as well as being able to be custom coloured. This makes it a popular choice for branding and marketing purposes.

Some of our Products made of Soft PVC

In our PVC production, soft PVC include items such as price pockets, heat pads, clear banner for separation walls and much more. Check these products out below and browse our shop to find exactly what you are looking for!Hard PVC

Hard PVC is also known as rigid PVC and has more mechanical strength than Soft PVC does. Hard PVC is a material that has not been formulated with plasticisers. This means that the PVC polymer chains have not been broken, and is therefore a more rigid and stiff material.Hard PVC has a higher tensile strength and tear resistance. Rigid PVC is more commonly used for applications that require a more rigid and durable material. These include products such as pipes and fittings.

Hard PVC can be thermoformed using heat bending processes. This is where a sheet of PVC is heated in the necessary points to bend it in the desired form or shape. The rod must reach a temperature where it is hot enough to soften the plastic, in order to bend it, but not too hot where it will melt the plastic.

The temperature can be set depending on which plastic is to be softened and formed. The temperature at which to heat bend is very important, because each type of plastic has different melting points to take into account.

Rigid PVC can also be printed in many different ways should you want to customise any piece. This plastic material can be printed either digitally or with screen printing.

Advantages of Hard PVC

- Mechanical strength

- Resistant to high temperatures

- Easy to machine and process

- Durable

Hard PVC is a very durable material with a very high tensile strength, which makes it a good material for structural applications. Since Hard PVC has a higher melting point than soft PVC, it also makes it the ideal choice for applications that require exposure to high temperatures. These applications include uses for building and contruction.

Hard PVC is rigid, which allows it to be drilled, cut, and shaped using a large range of tools and techniques. Being able to be shaped and formed allows Hard PVC to be easily customised.

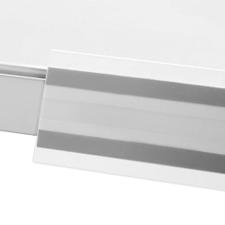

Some of our Products made of Hard PVC

In our PVC production, hard PVC includes items such as shelf edge strips, organiser bags, brochure display stands and much more. Check these products out below and browse our shop to find exactly what you are looking for!High-Impact PVC (HIPVC)

HIPVC also has the characteristic of being impact resistant, even higher so than that of regular hard PVC. With HIPVC being highly durable and resistant to physical stresses, it is an ideal material for applications such as pipes, window frames, flooring and roofing. It also has a higher temperature resistance of -30°C to +70°C. This makes high-impact PVC ideal for outdoor use.Although we do not currently offer products with HIPVC we do offer products made of High-Impact Polystyrene (HIPS). Click here to read more information on what HIPS is and how it is used »