Deep Drawing / Thermoforming

Working under high pressure? Not always!

Deep Drawing / Thermoforming

Here we use negative pressure. Thermoforming, also known as deep drawing or vacuum forming, is a method of converting thermoplastics. In this process, a semi-finished plastic product is attached to the edges and heated to the softening temperature using heating elements. A moulding tool is then moved against the board and air channels in the tool create a vacuum between the two.

The increased pressure of the atmosphere ensures that the flexible plastic material moulds itself to the wall of the mould. As the moulded part cools, the material returns to its rigid state.

Processing

- Vacuum Deep Drawing

- CNC milling

- Punching

- Sawing

- Welding

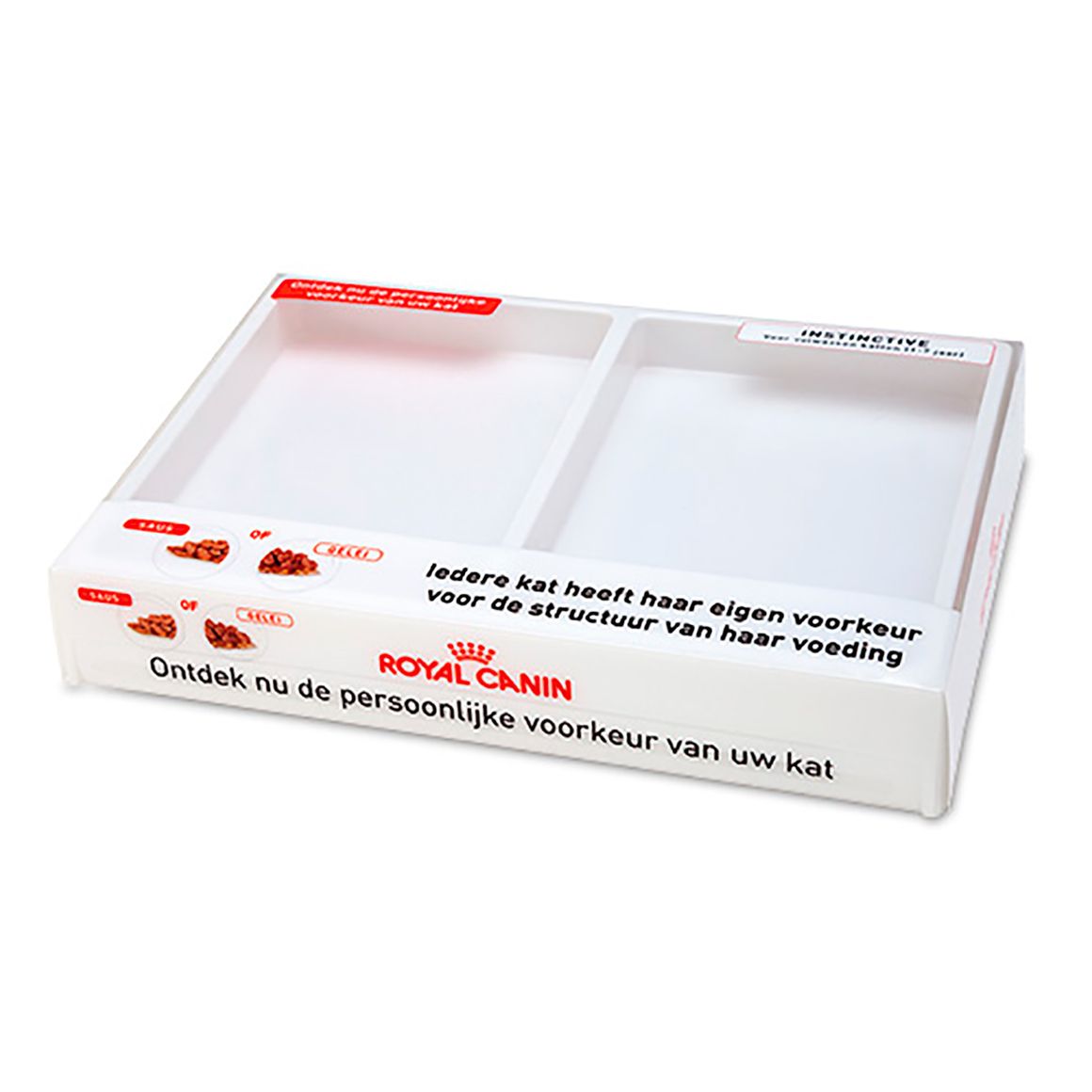

Examples of Special Displays